From Concept to Development: Unleashing Creativity With DTF Printing on Numerous Fabrics

In today's dynamic world of textile design, the utilization of Direct to Film (DTF) printing modern technology has transformed the process of moving intricate styles onto numerous textiles. The combination of advancement and creativity via DTF printing opens doors to a realm where imagination knows no bounds.

Checking Out the Benefits of DTF Printing

Why is DTF printing significantly favored over various other techniques for its adaptability and sturdiness in the fabrics sector? Direct-to-film (DTF) printing has been acquiring traction in the fabrics sector due to its various benefits that deal with the advancing needs of the market. One essential benefit of DTF printing is its flexibility in regards to the materials it can be related to. Unlike some standard techniques that are limited to details material kinds, DTF printing can be utilized on a large range of products, including cotton, polyester, blends, and even leather. This adaptability allows for higher imagination and development in fabric layout.

Furthermore, DTF printing provides exceptional longevity, making it excellent for producing long-lasting layouts on materials - DTF Printing. The prints produced with DTF are known for their vivid shades and resistance to fading, splitting, or peeling - making certain that the end product keeps its top quality also after numerous washes or extended use. This durability makes DTF publishing an affordable solution for makers aiming to produce high-quality, long lasting designs on fabrics

Designing With DTF: Advice

Creating successfully with DTF printing includes understanding the details of digital layout software application and understanding just how to enhance designs for the very best results on various materials. When producing designs for DTF printing, it is critical to take into consideration the material shade, appearance, and type to make certain that the final product satisfies expectations. Below are some suggestions and tricks to enhance your DTF design procedure:

Resolution is Key: Beginning with high-resolution pictures to keep clearness and sharpness in your designs. Low-resolution images can result in a pixelated final product.

Shade Matching: Focus on color precision when designing for DTF printing. Use color monitoring devices to guarantee that the shades in your design equate accurately onto the fabric.

Vector Graphics: Make use of vector graphics wherever possible to keep the top quality of your styles when scaling them to various dimensions. (DTF Printing)

Examination Prints: Constantly conduct test prints on example materials to inspect the colors, resolution, and overall design quality prior to major production.

Picking the Right Fabrics for DTF

When taking into consideration the optimal fabrics for DTF printing, the option of material plays a crucial duty in attaining the preferred top quality and sturdiness of the final printed styles. Fabrics with a high polyester content are commonly chosen for DTF printing due to their capacity to hold the ink well and create vivid prints. By meticulously picking the right fabric for home DTF printing, developers can boost the durability and visual effect of their layouts.

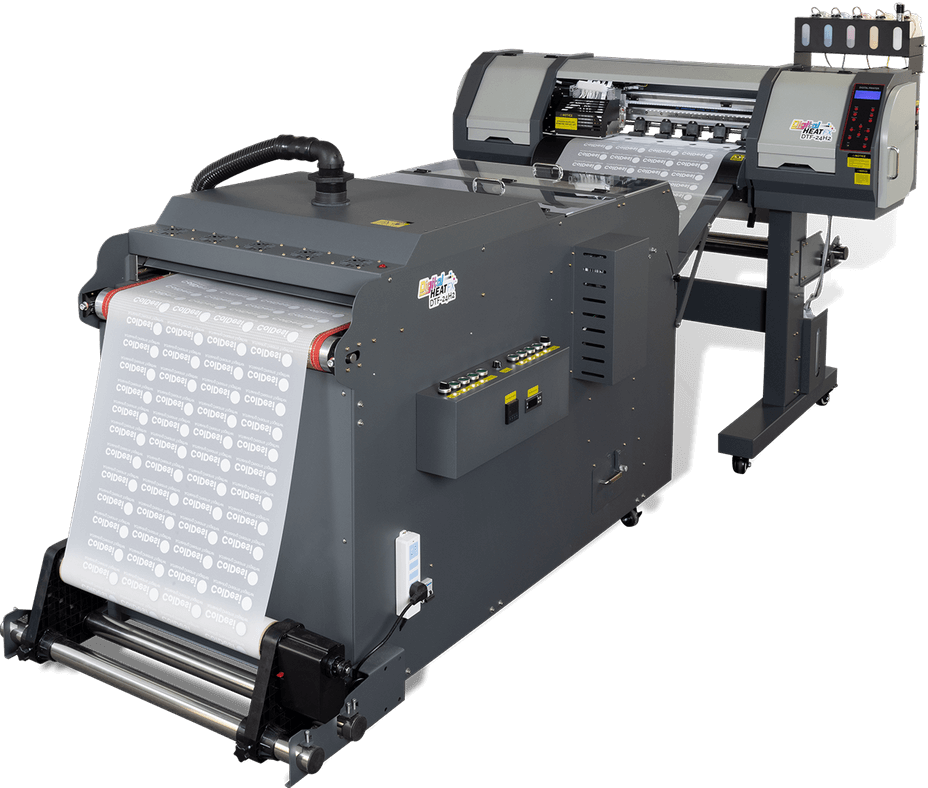

Step-by-Step DTF Printing Refine

After curing, the printed design is after that moved onto the fabric using a warm press. The transfer procedure needs mindful alignment to make sure that the design is used precisely. Once the transfer is complete, the material is allowed to cool before the transfer movie is peeled, leaving the lively and resilient layout on the material. The textile might undergo post-processing therapies to boost the layout's long life and vibrancy, resulting in a high-quality completed item prepared for use or display.

Showcasing DTF Work Of Arts

Have you ever before marveled at the elaborate details and vibrant shades of DTF work of arts showcased on numerous textiles? DTF printing has actually changed the means layouts are transferred onto textiles, permitting unparalleled precision and richness in colors. When these DTF masterpieces are placed on display, they mesmerize audiences with their striking visuals and meticulous workmanship.

One of the most captivating aspects of showcasing DTF work of arts is the flexibility it provides. Whether it's a vibrant and appealing layout on a tee shirt, an in-depth pattern on a pillow case, or a customized print on a canvas bag, DTF printing permits endless opportunities. This flexibility allows musicians and designers to unleash their creative thinking and bring their visions to life on a variety of fabrics.

Additionally, the resilience of DTF prints makes certain that these masterpieces can endure the examination of time without losing their vibrancy. Whether shown in galleries, put on as fashionable garments, or utilized as attractive accents in homes, DTF masterpieces proceed to excite audiences with their exceptional high quality and aesthetic appeal.

Verdict

Finally, DTF printing offers a flexible and ingenious technique why not find out more for releasing creative thinking on numerous fabrics. By exploring the benefits of DTF printing, designing with particular suggestions and techniques, choosing proper textiles, and adhering to a step-by-step printing procedure, musicians can display their work of arts with convenience. This process enables the seamless transition from concept to development, giving endless opportunities browse around these guys for imaginative expression.

In today's vibrant world of textile design, the usage of Direct to Film (DTF) printing technology has revolutionized the process of transferring detailed styles onto various textiles.Designing properly with DTF printing includes grasping the intricacies of electronic style software application and understanding just how to enhance designs for the ideal outcomes on various textiles.When considering the optimum materials for DTF printing, the choice of material plays an important function in accomplishing the preferred quality and resilience of the final printed layouts. The following action is printing the design onto a special DTF transfer movie utilizing a DTF printer with the suitable ink. By exploring the advantages of DTF printing, making with particular ideas and techniques, choosing proper textiles, and adhering to a detailed printing process, artists can display their masterpieces with convenience.

Comments on “DTF Printing Mastery: Raise Your Fabric Creations with Direct-to-Film Technology”